It was the age of flappers and jazz … but at Longwood Gardens it was more about industrial-strength classicism and illuminated fountains, thanks to the vision of Pierre S. du Pont. Mr. du Pont was in the technology business of chemistry and automobiles. He was building skyscrapers, chemical factories, and assembly lines, so it wasn’t hard to adapt technology to make fountains spurt and glow.

Longwood’s first fountain (1907), on the Flower Garden Walk, was supplied by gravity from a tank in the Peirce-du Pont House attic, which in turn was fed from a hydraulic ram at the Large Lake. No electricity was required since the power to push water uphill came from the water itself.

Longwood didn’t have an abundant water supply yet, especially in the early 1920s when more was needed for the new Conservatory. Mr. du Pont spent $50,000 (about $650,000 today) to build a water-powered pumping station at the Pocopson Creek to the east. This recalled the famous Machine de Marly that Louis XIV built to pump water from the Seine to Versailles. The Pocopson plant had a 20-foot-diameter water wheel; a 600-foot-long, 42-inch-diameter intake pipe to supply the wheel; three piston pumps powered by the wheel; and an 8-inch wood pipe to deliver creek water to Longwood’s Large Lake, which was three miles away and 200 feet higher. But the wooden pipe leaked, and the pumping station was later abandoned and the property sold. Wells were a more practical alternative.

Mr. du Pont noticed on his visits to Italian and French gardens that those fountains were gravity-fed from elevated reservoirs supplied by springs and aqueducts. When he started designing Longwood’s Italian Water Garden and expanded Open Air Theatre in 1925, he first contemplated a 100’ x 100’ x 6’ underground hilltop reservoir that would supply (via long pipe runs) the Theatre, Water Garden, and two Flower Garden fountains by gravity flow—350 gallons per minute (GPM) on Saturdays and Sundays, 140 GPM on weekdays, with 1,700 GPM comprising “a great display.” The reservoir would be filled by electric pumps. Pierre did pages of elaborate calculations, but ultimately he decided to build self-contained, individual recirculating pumping systems for each of the gardens, with the reservoirs not elevated. There is no question that he had a sophisticated knowledge of hydraulics.

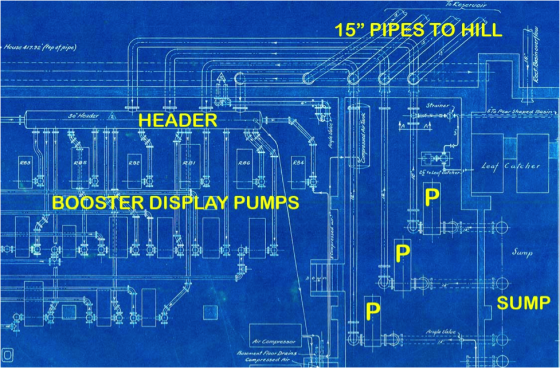

When designing the Main Fountain Garden four years later, Pierre built an elevated reservoir at the highest nearby spot (where the Eye of Water is now), on the hill south of the Rectangular Basin. One, two, or three 100-horsepower (HP), 4000-GPM electric supply pumps filled the 42,600-gallon reservoir through three 15-inch pipes that are buried in the hillside. Through “tee” connections, these same pipes also ran to a 36’ x 30” header (a giant manifold or supply pipe) in the pumphouse, to which all the fountain displays and their booster pumps were connected.

The water in the header was under pressure because it came from the elevated hilltop reservoir, and the pressure was enough to give a substantial daytime display through gravity flow, although the reservoir had to be continually resupplied by one 100-HP pump. When various booster pumps were turned on for a full or nighttime display, they boosted the already pressurized water even more, so that it shot up to 130 feet in the air.

Water pumped up to the hilltop reservoir that was not needed for the fountain display overflowed into the stream that supplies the Waterfall. This was an ingenious solution, since it was not necessary to know exactly how much water was needed for the changing fountain displays, as long as the minimum was maintained—an intentionally imprecise system with a large margin for error, considering the varying water needs as different displays were turned on and off.

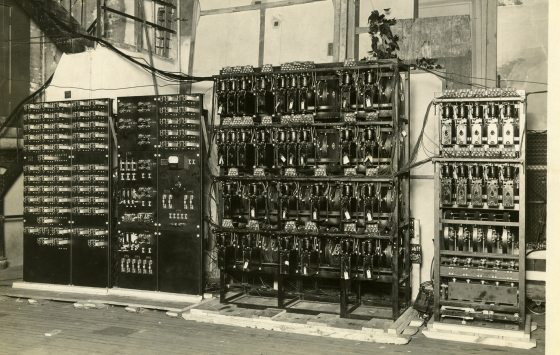

Until 1963 only one 100-HP pump was used to power the daytime fountains and a moderate waterfall, although at least two were always used at night. In 1963 a second 100-HP pump was energized for daytime use, which resulted in a roaring waterfall from the 4,000 additional gallons per minute. (The third 100-HP pump was a spare or backup pump if one of the others failed or needed to be serviced.) The original pumps, manufactured by Worthington, were in use from 1931 to 2014.

The Open Air Theatre had been revamped in 1926 with below-stage fountain lights using red, green, blue (RGB), and clear glass filters. But the primary RGB additive colors did not produce an acceptable yellow, despite color theory that said red and green light should produce yellow light. So in the Main Fountain Garden, yellow lights were added to give a five-color system (RGBYW). The more than 730 waterproof fountain lights were specially manufactured by Holophane. The reflector and lens were combined in a soup-bowl shaped housing, with a wide angle of spread and uniform intensity. The units cost $63,000. The prismatic reflectors, looking like cut-glass bowls, bounced light out without the use of silvering. The red, blue, green, yellow, and clear Pyrex lenses were made by Corning Glass Works and cost $4,248.

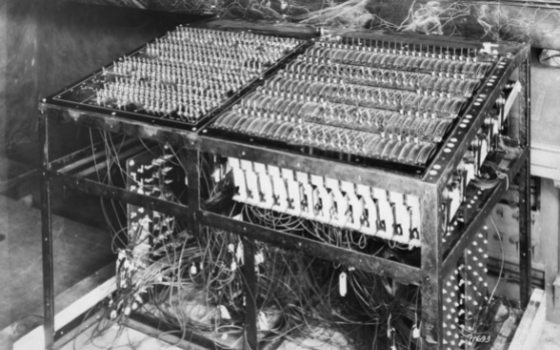

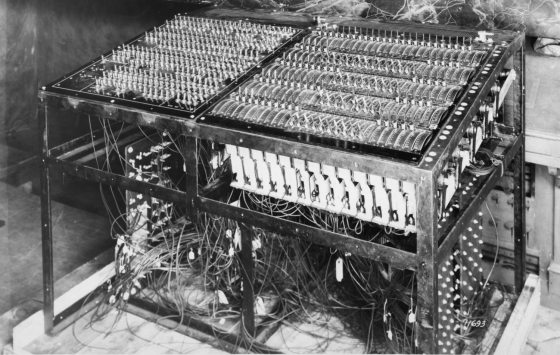

To operate the fountains, a special switchboard was devised by the electrical manufacturer Cutler-Hammer. It had moveable levers that controlled the direction and speed of motorized dimmers, as well as switches for all the pumps and fountain effects. There was also a cyclic color control system that would change the fountain colors automatically, but little is known about it.

No one was more instrumental in helping Pierre S. du Pont create these hydraulic wonders than Russell Brewer (1890-1965). He started working at Longwood in 1915 and ended up creating and heading the Maintenance Department. He, better than anyone, knew how to operate the fountain control board to, as he put it, “turn the stately streams of water into columns of beauty, and the floating masses of gauze-like spray into mystic grandeur,” with the “expressions of appreciation escaping from the lips of the awe-inspired audiences” giving “undeniable testimony as to the magnificence of this man-made wonder.”

So maybe there isn’t that much difference between sequined flappers and sparkling fountains. They both reflected the exuberance of an age that has long since vanished. But Longwood’s fountains will soon be reborn with the latest and greatest technology!