With its stunning European-inspired architecture, Italianate limestone sculptures, lush lawns, textural boxwood hedges, and—let’s not forget—a staggering 1,719 fountain jets that spring to life each May, the five-acre Main Fountain Garden is among Longwood’s most iconic, most beautiful spaces. It’s also home to some of our most precise features: three allées totaling 164 littleleaf linden trees. We meticulously maintain each allée in a uniform, classical horizonal square hedge; a design that not only provides a canopy of shade, but one that mirrors what’s often seen in Europe, further lending to the European feel of the garden. All that goes into maintaining and pruning these trees may surprise you … and now, with a new addition to the process, it’s more precise than ever.

Our Main Fountain Garden lindens were planted in the summer of 2016 as part of our Main Fountain Garden revitalization. To achieve the formal and classical appearance of their design, it’s imperative that we keep straight, crisp lines throughout the allées and all 164 trees. As the Main Fountain Garden is a sloped space, we have to factor in elevation changes throughout the garden as we prune them. Every tree is a different height from the next as the design was meant to play with perspective and each allée hedge was to meet perfectly.

A wide view of the allée in this May 2025 photo during our first hedging shows the slope of the Main Fountain Garden. Photo by Tyler Altenburger.

To achieve that look and keep our trees thriving along the way required some research. To that end, I had the pleasure of traveling to France for two weeks along with Longwood Horticulture Contract Manager Naomi McCafferty and P.S. du Pont Fellow Colvin Randall for a linden pruning query during the summer of 2018. While there, we visited more than 30 new and established gardens in public parks, chateaux, and municipalities from Chateau Chambord to Versailles. We walked more than 100 miles to study similar (and dissimilar) types of hedge aesthetics, as well as learn how and with what equipment, from lasers to tractors, that aesthetic had been achieved.

One key feature of these successful hedges we saw in many gardens and parks is termed the “Riviere de Lumiere” or “river of light” in which a small space is allowed between opposing trees along an allée. This river of light allows for adequate light penetration among the trees, so they get the space and sunlight they need while still resembling a solid hedge, as well as allows room for equipment access. We decided to utilize the river of light approach in our own Main Fountain Garden, maintaining a canopy height of 8 feet at the bottom of the lindens, so guests can walk safely under our trees while still allowing for a low, intimate feel along our allées.

The “River of Light” effect in our allée. Photo by Hank Davis.

Pruning these trees accordingly while keeping them healthy and thriving has taken a lot of research, a lot of calculations, and a lot of steady hands. A new concept, however, has led to even more efficiency in our process: a new, custom hedging implement, specifically engineered to help us maintain our Main Fountain Garden allées to our very precise standards.

During our initial 2018 trip to France, we started to lay the groundwork for this custom piece of equipment, researching manufacturers that specialize in such equipment—those who can build such equipment are located in Europe as this is a common piece of equipment used in the vineyard and agriculture industries, in addition to formal tree shearing in gardens and along city streets—and understanding the features and specs we would need. We also needed a manufacturer and dealer that supported such machines.

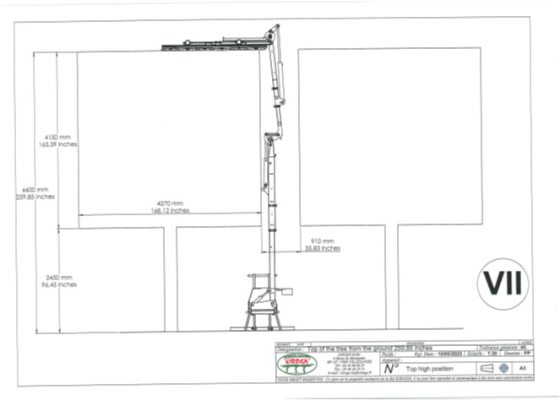

Calculating the dimensions of our Main Fountain Garden hedges and comparing them to what was commercially available, we realized our equipment would need to be custom-built. From there, we got to work on overseeing its design and build—measurement by measurement, piece by piece.

Working with a distributor in California and a manufacturer in France, we utilized computer-aided design to modify an off-the-shelf unit to fit our hedge dimensions. We had a lot of unique needs for our hedging machine, including making sure it was the proper size to fit within the allées. An additional hydraulic pump was added to allow for seamless adjustment of the implement while not impacting the cutting blade speed. The unit needed to be big enough to reach up and over, but small enough to fit into the intimate space. Many hedges in Europe are along roadways which allow access for large equipment.

Utilizing computer-aided design and the measurements of our Main Fountain Garden, we modified an off-the-shelf unit to meet our needs.

During our 2023 trip to France, we were able to see a concept of our implement in process with a demonstration. Photo by Tyler Altenburger.

The tractor that carries the implement needed a creeper gear, which allows the tractor to travel very slow, to provide a very precise, very high-quality cut—but doesn’t come standard. We needed down-facing exhaust so the exhaust dissipates beneath the tractor and not upwards, which could burn our trees. We needed a front hitch—standard in Europe, but minimally used in the US. This allowed further adjustment to raise and lower the implement as we prune and makes it easier to remove the implement if we use the tractor for other uses in the off-season. The tractor needed to be large enough to allow for necessary hydraulic pressure, but still small enough to fit within the allées. And above all, we needed to make sure we were designing equipment that helps us best care for our trees.

The custom-built machine required a lot of thought and a lot of calculations—even a handmade brick-toy model, and a few foam and paper models of the hedges along the way to help us visualize and explain what we needed. But after six years of coordination, a lot of math, a couple trips to France to see the equipment in action and check on the measurements, the implement air-freighted from France, the tractor supplied by a local supplier, and the implement and tractor mated together, our custom hedging machine is here—and we couldn’t be more excited.

The custom implement arrived at Longwood in early 2025 … but it had to be shipped in pieces, so we got to work unboxing and reconstructing! Photo by Tyler Altenburger.

Our new tractor and implement are shown here together as our complete hedging machine goes through its final set-up tests. Photo by Tyler Altenburger.

As the machine is so specialized, since it arrived we’ve been hard at work training dedicated members of our arborist team on its operation. Over the winter and early spring months (while the Main Fountain Garden lindens were dormant and not yet ready for pruning), the team spent time each week practicing. Initially, operators needed to learn the new tractor and started with basic tractor skills to running the implement in conjunction with the tractor.

Once comfortable, we practiced pruning with the new equipment at our woody plant nursery where we have various species of trees available for practicing. It allowed the team to get a feel for how it runs and seeing the quality of its cut. Photo by Tyler Altenburger.

Before cutting in the Main Fountain Garden, we did dry runs, adjusting measurements outside of the tree’s canopy to ensure the lasers, receivers, tractor and implement all functioned together seamlessly. Photo by Tyler Altenburger.

Our first official hedging with the new machine took place in early May 2025. Here, Senior Arborist Luke Salata navigates the river of light. Photo by Tyler Altenburger.

Our first official hedging with the new machine took place the week of May 5. The team has spent years preparing for this and it went off without a hitch. While the team has spent countless hours practicing, training, and discussing, maneuvering the equipment into the Main Fountain Garden for the first time was the most helpful. The team learned a great amount about the new machine, the techniques we’ve laid out over the past few years, and new ideas to make the entire process safe and efficient. Each time the team hedges, the process will become more efficient.

Senior Arborist Dylan Drake heads north on the eastern allée during the first days of shearing. Photo by Tyler Altenburger.

Although it has been a long time coming, our new machine will undoubtedly save our team time when pruning and allow for more pristine, precise cuts. And while it’s guided by a transit laser, the machine does not operate on its own—far from it. An arborist must drive the tractor while controlling the implement precisely, using the receiver to translate where the cutting implement needs to be moved to. It’s still very much a calculated, human-run process—and it’s still one that will take time. Remember the custom creeper gear? When we prune our lindens, we will run the machine is creeper mode while cutting—it’s a very slow process, but moving slowly (roughly 0.25 miles per hour) provides a high-quality cut.

The entire pruning process takes about a week, and we will prune the lindens upwards of three times per year. Photo by Tyler Altenburger.

Watch parts of our first Main Fountain Garden hedging process with this quick, sped-up timelapse. Video by Carol Gross.

It's this attention to detail, this commitment to precision that helps set Longwood apart, and makes experiences like a stroll through our Main Fountain Garden so very special. We look forward to seeing you there.